When combustible materials are in a finely divided dust form, they can burn rapidly. If the dust is suspended in the air in the right concentration, under certain conditions, it can become explosible. Even materials that do not normally burn in larger solid amounts (such as aluminum or iron), given the ideal conditions, can be explosible when they are in dust form. The force from such an explosion can cause employee deaths, injuries, and even destroy an entire building.

A wide variety of materials that can be explosive in dust form exist in many different industries. Some examples of these materials include food (such as flour, feed, sugar, etc.), grain, tobacco, wood, paper, pulp, cotton, rubber, pharmaceuticals, coal particles, and metals (e.g., aluminum, chromium, and magnesium). These materials are not only used in a wide variety of industries but in many different processes, including agriculture, chemical and pharmaceutical production, furniture manufacturing, and many others.

The National Fire Protection Association (NFPA) has developed a number of consensus standards to address the consequences of combustible dust explosions. The NFPA consensus standards are designed to provide guidance on dust explosion prevention and mitigation by controlling fuel sources (like combustible dust), ignition sources, and dispersion of dust particles. The Occupational Health and Safety Administration (OSHA) initially announced the National Combustible Dust Emphasis Program in 2008 and then updated it in 2015 to address combustible dust.

Although OSHA does not have a combustible dust standard, they do inspect for combustible dust and issue fines. Typically, the General Duty Clause is cited, as the NFPA standards detail the risks, hazards, and mitigation procedures for workplaces and employees.

The Hazards

Five elements must be present for a combustible dust explosion to take place:

- Fuel

- Oxygen

- An ignition source (heat or spark)

- Dispersion of dust particles

- Confinement of the dust cloud

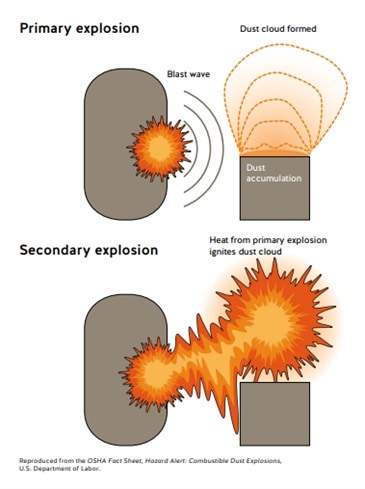

When dust accumulates over a period this creates a danger when exposed to an ignition source. Alternatively, if the dust is disturbed by an explosion, the dust itself will cause a secondary explosion. In other words, the pressure that travels through a work area will displace the dust that serves as fuel for a secondary explosion. The Chemical Safety Board (CSB) states that most of the fatalities and the devastating injuries suffered during these explosions are caused by secondary dust explosions.

Safety Precautions

It is understandable that good housekeeping is critical in minimizing dust explosion hazards. Worksites that are well-maintained have fewer fires, explosions, and other accidents. These sites are safer overall.

OSHA offers the following tips on combustible dust safety:

- Implement a hazardous dust control program that includes dust inspections, testing, and good housekeeping practices.

- Equip the worksite with proper dust collection systems and filters.

- Regularly inspect the entire work area for dust residue.

- Use vacuum cleaners that are specifically approved for dust collection.

- Ensure that all employees are trained on the hazards of combustible dust.

- Always use proper electrical equipment in hazardous locations.

The following are suggestions for controlling ignition sources:

- Ensure that appropriate electrical equipment and wiring methods are always used.

- Develop an ignition control program that includes grounding and bonding and other methods for dissipating any electrostatic charge that could be produced while transporting dust through ductworks.

- Control the use of open flames and static electricity.

- Do not allow employees to smoke near the facilities.

- Keeping all heated systems and surfaces clear of combustible dust.

If your workplace contains combustible dust, it is critical that you follow OSHA’s safe work practices to prevent explosions and keep workers safe. EH&S management software can help you comply with OSHA’s combustible dust regulation in a streamlined and organized manner.

With the aid of EH&S management software, user communities can:

- List the known areas where combustible dust is a concern.

- Track air quality and testing information (atmospheric hazards).

- Store and organize combustible dust accumulation locations, photos, and information all in one central location.

- Document combustible dust inspections.

- Inventory dust collection systems and set filter change schedules.

- Compile lists of workers who are qualified to conduct audits.

- Store training information.

- Track combustible dust incidents and corrective actions.

Software can assist a company with the administration, documentation, analysis, and tracking of combustible dust hazards all without generating a pile of paperwork. It can help managers assign combustible dust awareness training and automatically send reminders to employees when they are due for training.

Employers cannot afford the cost of allowing hazardous combustible dust to accumulate in the workplace. Using EH&S software to meet compliance with NFPA regulations means saving company time, ensuring no aspect of the regulations goes overlooked, and greatly reducing the possibility of a combustible dust explosion in the workplace.

Author Bio

The SafetyStratus Research Advisory Group (RAG) brings together thought leaders from the global environmental, health, and safety community to promote best practices and provide key insights in the profession and the industries they serve. The Research Advisory Group also advocates, where practical, the intersection of and advances with the use of technology, such as the SafetyStratus enterprise EHS software platform. Group membership consists of representatives from across varied disciplines and market sectors as well as select members of the SafetyStratus team.

The primary objectives of the SafetyStratus RAG partnership are to:

- Build a strategic partnership between EHS practitioners and the SafetyStratus team.

- Provide engaging and practical content to the global EHS community.

- Provide discipline and market feedback specific to SafetyStratus products and services.

While the objectives of the RAG are varied, the primary public-facing outcome will be available through engaging and practical content found on the SafetyStratus resource pages. Various articles, papers, and other valuable resources will be produced and shared as part of an ongoing effort to cultivate a robust community. Ultimately, the SafetyStratus RAG will expand to have a broader reach and provide opportunities for more inclusion by all interested EHS professionals in a collaborative community environment.